Filter press equipment | Industrial filter press equipment list

Stay with us to learn more about filter press equipment.

VisitCount 74

:Filter press equipment

When discussing filter press equipment, it is important to first understand that the design of a filter press is determined by the volume and type of slurry that needs to be dewatered and purified. Accordingly, a filter press consists of the following components

- Filter press plates

- Filter press chassis or body

- Filter press vibration system

- Filter press plate washing system

- filter press cloth

- Filter press hydraulic system

- Filter press tray

- Filter press electrical panel

In the remainder of this article, we will examine each of the components listed above and discuss the construction of a filter press. It is worth noting that a filter press is one of several critical components in a wastewater treatment system.

filter press plates

Filter press plates serve the following functions:

- Enclosing the flocculant-laden sludge

- Applying compression

- Channeling water out through very fine filtration paths

The filter press consists of multiple plates aligned in sequence. As slurry flows through the filter cloths, the plates are compressed by a hydraulic system. This pressure separates solids from liquids, allowing clean water to exit while solids are retained between the plates.

The resulting solid material, known as filter cake, has various applications. Danafon Company has implemented a specialized method to facilitate the collection of this cake, which keeps the surrounding area clean and enables easy handling and transportation.

Material and Design Considerations

Filter press plates are typically made from specialized polymers for the following reasons:

- Continuous exposure to water

- Corrosion and oxidation resistance

- High maneuverability

- Sufficient resistance to applied pressure

- Appropriate elasticity

- Lightweight for ease of handling, assembly, and repair

Depending on the customer's needs and application, plates may be manufactured from Teflon, steel, polypropylene, cast iron, aluminum, or rubber.

Denafonoon Company offers plates in the following standard sizes:

- 60 × 60 cm

- 80 × 80 cm

- 100 × 100 cm

- 150 × 150 cm

The number of plates used can range from 10 to 70, depending on the customer's filtration requirements. Special porous fabrics are also designed to cover the plates and prevent the passage of solid particles.

It is important to consider both the number and type of plates when purchasing a filter press. For more detailed information on filter press fabrics, please refer to the related section in this article.

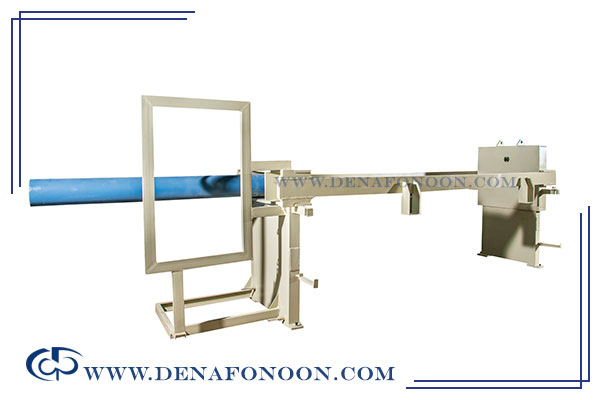

Chassis (Body) of the Filter Press Machine

The chassis, or body, of the filter press acts as the structural backbone of the machine. It provides:

- Mechanical support

- Structural integrity

- A secure framework to hold all filter press components in place

The main function of the chassis is to support the filter press plates and absorb the mechanical stresses exerted during operation, particularly from the hydraulic compression system.

Vibrating System of the Filter Press

The vibrating system facilitates the release and discharge of the cake formed between the plates. After the plates are opened, some cake falls off naturally, but some residue may remain stuck. The vibration system automatically activates to shake off the remaining cake.

One of the key advantages of Danafon Company’s filter press is the modern and efficient design of its vibrating system, which meets the latest industry standards and ensures precise operation with minimal error.

Vibration Process Workflow

- Vibration motors, typically mounted near the plates, are activated.

- Vibrations are transmitted to the plates.

- The cake detaches from the plates due to inertia and vibration.

- If a collection basket is present, the cake is discharged into it; otherwise, it falls to the floor.

- The vibration system then turns off automatically.

Benefits of the Vibrating System

- Enhances overall machine performance

- Increases filtration efficiency

- Speeds up cake discharge

- Ensures complete cake removal from between plates

- Prevents clogging of plates

- Minimizes machine downtime, which is critical in industrial operations

Filter press plate washing system

The operation process of the filter press plate washing system is as follows: the plates are opened individually, then a complete washing is performed. Afterward, the washed plate is closed, and the next plate is opened. This system is applicable for any number of filter press plates, but it is more logical and justifiable in cases with a higher number of plates.

filter press cloth

The filter press cloth is one of the key components in filter press systems, used for separating solid materials from liquids. These cloths are typically made from durable materials such as polyester, nylon, or carbon. Different types of filter press cloths have various applications and are specifically designed to withstand high pressure and harsh environmental conditions.

The main role of the filter press cloth is to act as a physical filtration medium, allowing liquids to pass through while retaining solid particles. These cloths are commonly used in various types of filter presses, including low-pressure, medium-pressure, and high-pressure models. Depending on the application and type of materials, they have specific characteristics such as precise pore sizes or resistance to temperature and chemicals.

Hydraulic System of the Filter Press

Another important component of the filter press is its hydraulic system, This system is designed to apply pressure to the Teflon plates, in accordance with the pressure of the homogenizing pump, using a special hydraulic cylinder dedicated to the filter press.